|

|

|

|||||

|

go to: HOME PAGE

Reloading Accessories

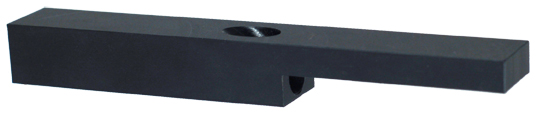

The DAA Extra-Short Dillon Powder Bar was developed to meet a specific need, created with the introduction of the Dillon XL750 press: In the 750, the Dillon Powder Measure is angled such that the powder bar must extend directly over station #4 in the toolhead, and it cannot be repositioned. This Is not an issue if you have a short die in that station. However, if you wish to run a powder check in station #3, and a bullet dropper in station #4, as many do, this creates a serious problem. The original Dillon Powder Bar is too long, and it will extend and impact the bullet dropper in station #4, preventing correct function. In order to resolve this problem, we designed an innovative extra-short powder bar that shortens the extension range towards station #4 by a full 30mm (1.15”), resolving the issue. When fully extended, our charge bar stops short of contacting a Mr.Bulletfeeder Dropper or Mini Mr.BF tube assembly. The charge capacity of the Extra-Short bar is approx. 95% of the Original Dillon small charge bar. This design does require the use of a 2.5mm Allen key (not included) to adjust the powder charge, and the Click-Adjustable screw has 12 clicks per rotation for precise charge setting. Made from black anodized 6061 Aluminum.

DAA Magnetic Powder Check

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A103136 |

DAA Magnetic Powder Check |

$110 |

The DAA Magnetic Powder Check (US Pat. Pending) is a great addition to any progressive reloading machine, helping to ensure the quality and safety of your reloaded ammo.

The unique new design uses a high-tech Reed Sensor and a magnet assembled to the plunger Rod, to assess if the charge in the case is of the correct height.

This original design also provides, for the first time, an adjustability option. By bringing the Reed Sensor closer or further from the magnet, you can determine how forgiving the powder checker will be, or how much of a range of variance in the powder level should be acceptable without sounding the alarm. At its most sensitive, the accepted height variance is about 2mm, which correlates to a powder error of less than +-0.5 grain. More than sufficient to pick up any of the mistakes we are checking for, such as a double-charge, debris in the case or a case without powder.

The DAA Magnetic Powder Check assembles onto a station immediately after your powder dropper, screwing into a standard die thread 7/8-14 station. However, unlike other powder check systems, the DAA product does not require a dedicated hole drilled through the tool head next to the station! It can be used on ANY progressive reloader which has an available station after the powder drop.

A powder-check does require the use of a station in your toolhead, so if you do not currently have an available station, you may need to combine your seating and crimping into one station using a 2-in-1 seat/crimp die to free up a station. These too are available from mdgardner.com.

Summary of features and advantages:

A102917 |

PSP Brush for the 650/750 |

$25 |

A102918 |

PSP Brush for the 1050 |

$25 |

OK, I had to try it while getting this together. It really does work as advertised!

The DAA Powder-Spill-Prevention (PSP) Brush is a simple yet efficient reloading accessory that solves a real issue: How to prevent small amounts of powder being spilled out of the case, as the tool head of the progressive reloading press indexes?

This problem is even more acute for reloaders using Autodrive systems on their Dillon machines, in which case you cannot use your hand to stabilize the case, as the shell plate indexes forward. Especially when reloading very full cases, powder spill can have a real influence on the accuracy of the ammo you are producing, and the accumulating powder on your shell plate can prevent the smooth function of your press, and require frequent cleaning.

This problem is even more acute for reloaders using Autodrive systems on their Dillon machines, in which case you cannot use your hand to stabilize the case, as the shell plate indexes forward. Especially when reloading very full cases, powder spill can have a real influence on the accuracy of the ammo you are producing, and the accumulating powder on your shell plate can prevent the smooth function of your press, and require frequent cleaning.

Introducing the DAA PSP brush solution. Just magnetically click this part onto your Dillon press, and immediately your powder spill issues will be greatly reduced or completely eliminated. You’ll be able to index your shell plate faster, and produce more consistent, accurate ammo, while keeping your shell-plate clean and powder free.

A102427 V2 |

Click adjustable powder knob |

$40 |

The DAA Click-Adjustable Powder Knob V2, is the 2nd generation offering from DAA. Building on the experience and feedback of the first model, this one is, simply put, better!

The two piece aluminum structure eliminates the need to tie the base piece to the powder dropper, and the assembled spring-loaded steel balls (2 of them, for smoother function) make assembly a breeze. (No more battling with trying to keep the steel ball in place while assembling the knob!) The DAA Click-Adjustable Powder Knob V2 makes setting and adjusting your powder charge much easier and more precise.

The large 32mm round, aluminum machined and laser engraved knob, is knurled around the outer edge making it easy and convenient to rotate the bolt and adjust the charge. The two piece system includes two spring-ball assemblies, which click over pockets in the back of the knob, creating loud audible clicks to accurately rotate the dial in steps of 18deg, 20 clicks per rotation. These adjustments are easily small enough for any practical adjustment of the measured powder charge.

The laser engraved dial indicates direction for increasing or decreasing the charge, and the numbers make it easy to keep track of what the correct position should be for one load or another. The DAA Click-Adjustable Powder Knob V2 assembles in seconds on your existing Dillon powder dispenser adjustment bolt. A 2mm helen key is required (not included).

Designed for use on the Small Dillon Charge bar. Does not fit the large Rifle charge bar!

UT310 |

2x Powder Hopper Tube |

$45 |

If you reload large capacity rifle cartridges, large quantities of pistol cartridges for competition, or use "fluffy" high load density powders like IMR Trail Boss, you know how frustrating it is to have to stop frequently to fill the powder hopper on your Dillon press. Ever wish you could "Super Size" your powder hopper? Now you can! The 2X Powder Hopper Tube™ doubles the powder capacity of your Dillon Auto Powder Measure by replacing the original 7" powder hopper tube with a 14" powder hopper tube.

Fits both the Dillon Auto Powder Measure and the Dillon "Belted Magnum" Powder System!

The 2X Powder Hopper Tube™ is made from high-strength, clear, poylcarbonate tubing that will not stain or discolor from extended contact with most gunpowders.*

Our Precision Powder Baffle™ is included and provides a uniform flow of gunpowder to the powder bar, regardless of the powder level in the hopper. The powder baffle is made from 20 gauge aluminum and is water-jet cut to precise dimensions.

Easy Installation! Just empty the powder measure, remove the two screws attaching the original powder hopper and lift off the powder hopper tube. Insert the 2X Powder Hopper Tube™ and attach using the original screws. You even get to use your original Dillon powder measure lid.

Compatibility with Dillon Low Powder Sensor If you use a Dillon Low Powder Sensor, it will still fit but will alarm at 50% full unless you modify it with a longer follower rod. Extending the follower rod is easy and inexpensive and instructions are included.

UT330 |

Powder Measure Drain-N-Change |

$25 |

The Powder Measure Drain-N-Change™ Tool Allows users of Dillon reloading presses to drain gunpowder or change powder bars without removing the powder measure from the toolhead or press.

Just 1 Drain-N-Change™ Tool Services ALL of your Powder Measures! Since the Drain-N-Change Tool is only used while draining powder or changing powder bars, and not a permanent installation, you only need one tool to service all of your powder measures.

The Powder Measure Drain-N-Change™ Tool drains 100% of the powder from the powder measure hopper, leaving the powder measure completely empty and ready to be filled with the next gunpowder.

The Powder Measure Drain-N-Change™ Tool drains 100% of the powder from the powder measure hopper, leaving the powder measure completely empty and ready to be filled with the next gunpowder.

Fits all versions of the Dillon Auto Powder Measure. Does not fit the older, manually operated Dillon Powder Measure as it uses a smaller size (narrower) powder bar.

Operations You can Perform:

UT340 |

Micrometer Powder Bar Kit |

$95 |

The UniqueTek Micrometer Powder Bar Kit™ upgrades your existing powder bar to a micrometer powder bar. No more guessing how many turns of the adjustment screw will get you back to that perfect powder weight.

Much more than just a dial or knob – the Micrometer Powder Bar Kit™ replaces the original 1/4-28 adjustment bolt with a true precision micrometer with 40 threads per inch. You will be able to return instantly to any powder weight setting with a speed and an accuracy never before possible. Of course, you still must weigh and confirm all powder weight setting changes.

Much more than just a dial or knob – the Micrometer Powder Bar Kit™ replaces the original 1/4-28 adjustment bolt with a true precision micrometer with 40 threads per inch. You will be able to return instantly to any powder weight setting with a speed and an accuracy never before possible. Of course, you still must weigh and confirm all powder weight setting changes.

Fits all Powder Bar sizes. Also fits SL 900 Powder Bar and Shot Bars!

Kit includes: Micrometer head, LocTite® and installation instructions. Powder bar is not included.

UT345 |

Arrendondo Powder Drop Slide with Micrometer 550/1050 |

$155 |

UT350 |

Arrendondo Powder Drop Slide with Micrometer SDB/650 |

$155 |

If you use Vectan SP2 or other super fine grained powders, you know how the powder can leak around the powder bar and even jam the Dillon powder bar. The Arredondo Accessories plastic Powder Drop Slide has been proven to cure this problem.

You get all of the advantages of the Arredondo Powder Drop Slide PLUS our Micrometer Powder Bar Kit™!

Need super small powder drops? These powder drop slides are customized, exclusively for UniqueTek, to allow even smaller powder drops than the standard Arredondo Powder Drop Slide. They will meter down to 0.7 grains (with Win 231) and they meter very small powder drops more accurately than the Dillon extra-small powder bar. If you are loading small centerfire cartridges like the .32 S&W Long for ISSF Center Fire Pistol and other target competition, this is THE powder bar to use!

Advantages:

ORDERING NOTES: Due to the different orientations of the powder measure on the various Dillon presses, the powder drop slide is available with the micrometer installed in one of two orientations. If you do not make a selection, you will be sent the UT350 for the RL 550B/Super 1050 presses.

Although the micrometer index marks will read upside down on the XL 650/750 or Square Deal B, this orientation provides better visibility of the micrometer and easier powder weight adjustment. Please indicate your choice by part #.

Bti520 |

Powder Trickler |

$35 |

The Frankford Arsenal Powder Trickler allows very small amounts of powder to be dispensed to achieve precise load weights. Dust/moisture covers protect powder while in the trickler. The Frankford Arsenal Powder Trickler is designed to work for all powder types, scales and supporting reloading equipment.

- Synthetic Dust Cover that doubles as a non-skid base

- Increased height to fit almost all powder scales

- Large powder capacity Heavy machined steel to prevent tip overs

UT320 |

Precision Powder Baffle |

$10 |

This is the same Precision Powder Baffle™ we designed for our 2X Powder Hopper Tube™. It also fits inside the original Dillon powder hopper and provides a uniform flow of gunpowder to the powder bar.

Fits in both the Dillon Auto Powder Measure and "Belted Magnum" Powder System. It only takes a few seconds to drop it down into the bottom of the Dillon powder hopper. The powder hopper is not modified and your Dillon Warranty will not be affected.

Fits in both the Dillon Auto Powder Measure and "Belted Magnum" Powder System. It only takes a few seconds to drop it down into the bottom of the Dillon powder hopper. The powder hopper is not modified and your Dillon Warranty will not be affected.

Primer-Related

|

DAA Primafill

The Double-Alpha PRIMAFILL is a semi-automatic primer-tube filling solution, able to quickly and easily fill both Small and Large primer tubes. It allows you to switch between Small and Large primers instantly, without tools or assembly. The PRIMAFILL can be used with any primer tubes which have an 8mm outer diameter, such as Dillon, or DAA tubes. It does not require a custom adaptor piece fitted to the tube, as other competing products require. So using the PRIMAFILL, you will be able to fill all your primer tubes! The Extra-Large flip-tray area is convenient when emptying large primer boxes, such as Federal and others. The tray is large enough for the entire box to fit over. The PRIMAFILL is powered by a regular 9v battery (not included). A momentary ON switch falls naturally under your index finger as you hold the device for right hand use, with your thumb centered on top of the lid. Hold the button down as you feed the primers into the tube, and release as soon as the last primer vanishes down the exit hole. Since this action should take 20 seconds or less, one battery charge will last for many thousands of primers. The spring-loaded orange latches incorporated into the output posts enable you to snap a tube into place, or remove it, instantly without any twists or turns, the latch falls naturally under your thumb: you press down on it as you insert the tube up, and you press up on the latch as you extract the tube downwards. An Easy and natural apposing thumb action. Primer tubes and battery are not included! Please Note:

|

||||||||||||||||

|

DAA Primer Flip Tray

A Primer Flip Tray is a “must have” item for most reloaders. The DAA Primer Flip Tray is made larger than most, and square in shape, to make it easier to empty a box of primers onto the tray. Even the very large box of the popular Federal primers easily fits within the footprint of our tray. Much experimentation and finetuning was done on the serrations to make the tray as efficient and fast to use as possible. Just a few shakes of the wrist will flip all your primers Anvil side up. The tray is made from a tough translucent plastic material, making it possible to see the primers through the tray as you flip it over enabling you to keep the primers well spread out for easy pickup. But the most unique and innovative feature of our primer tray, solves an irritating issue well known to all primer flip tray uses! Other Primer Flip Trays all have a sharp cornered side-wall on their lids. Because of this, when primers are close up against the side-wall they are very difficult to pick up. This forces uses to shuffle the tray to move the primers away from the wall. However, the lid of the DAA Primer Flip Tray has a side-wall which is a 45 degree angled slope. This allows you to easily pick up the primers even when they are tight up against the side wall of the lid, saving you valuable time as you fill your primer tubes. |

||||||||||||||||

|

DAA Small Primer Tubes

Blue Anodized pipe and end pieces for LARGE Primers, Red for SMALL. The DAA Primer Pickup Tubes are made of the highest quality aluminum, produced using custom-made extrusion tools and tightly controlled for accuracy and finish. Close attention is paid to the consistency of the internal and external chamfering to ensure optimal feeding. The matt-finish anodizing makes identifying the primer size immediate, while giving these tubes a striking attractive look. Blue Anodized pipe and end pieces for LARGE Primers, Red for SMALL.

The Pick-up end is engineered to provide a more ergonomic shape, making it much more comfortable to grip in one’s hand. A very noticeable improvement for those loading many tubes in one session. The wider, larger finger-support area, with its smooth support ring, prevents hand fatigue and cramping, as you do not need to close your fingers as tightly, like you do with other tubes. The tip was redesigned as well, and includes two “teeth” (not one, as others do). Carefully designed deep slots provide just the right amount of flexibility. The dual teeth work in union to pick up the primer horizontally while creating just enough pressure to ensure a firm grip on the primer while they are picked up. Both the Pickup and drop ends are made of translucent material making it easy to see the primers as they slide through the pipe ends. This is particularly handy when emptying the tube into your press, as you can easily see when they are all through. These end pieces slide onto the tubes with a firm fit to ensure they do not come off accidently. When assembling your tubes, make sure you press the ends all the way down onto the pipe, as leaving a gap can create a functional issue. |

||||||||||||||||

|

DAA PRIMER-PRO Collator

The PRIMER-PRO by Double-Alpha is a unique new approach to handling primers, and the solution reloaders have been waiting for! As any reloader knows well, manually filling primer tubes can be the most time-consuming and aggravating step in the whole reloading process, and few good automated solutions exist. The PRIMER-PRO uses a collator type solution where the primers are allowed to exit the bowl through 20 precisely formed channels, ONLY if they are orientated in the correct direction (Anvil side up). If they are Anvil down, they will not pass through the channel, and rather slide back into the bowl as their channel reaches the top of the rotation, to enter again later, correctly oriented. This rejection-type design makes it practically impossible for a primer to enter the output channel if incorrectly orientated, making this device extremely reliable. As the primers slide down the covered output-chute, they pass through an optical sensor which counts them and stops the collator once 100 primers have been counted into the primer-tube. The electronic processor board also monitors the sensor and is programed to stop the collator if, for whatever reason, primers hang-up on the exit hole and stack up along the ramp. The collator will be stopped before the primers stack all the way up and jam the collator. In such a case, the LED will flash quickly to indicate there is a problem. Once cleared, pressing the start button again will allow the collator to run and the count will continue from where it was stopped. Or alternatively, a long press on the button will start the count a new. One of the most innovative design solutions of the PRIMER-PRO is the Output Actuator Arm, which is activated by a lever system off the Timing Disk at the bottom of the Collator Assembly. This Output Actuator Arm slides the primers from the bottom of the ramp slide, moving them over to above the output hole, holding them there for a split second to ensure they are static, horizontal and stable, and then retracting to allow the primer to fall cleanly down into the awaiting primer tube. This dynamic solution for the exit hole greatly reduces the chance of primers hanging up while exiting into the tube, a problem common with other automated primer fillers. The PRIMER-PRO is currently available only for Smaller Primers, and handles Small-Rifle or Small-Pistol Primers equally well. A Large primer version may be offered in the future. One Magnetic Collar for a Dillon Primer Tube is included with the unit. Since the PRIMER-PRO can refill a single Primer Tube faster than you can use the previous 100 primers in any reloading press, only one tube is strictly necessary. However additional Magnetic Collars can be purchased separately, for those who prefer to fill multiple tubes before starting their reloading session. NOTE: Primer tube not included.

|

||||||||||||||||

|

Primer Track Bearing for the 550C press

The UniqueTek 550 Primer Track Bearing has a 1.4" extension that supports the primer bar better. This extended support prevents the primer bar from "drooping" and binding while its in the "out" position. The top surface of the bearing has also been coated with a Molybdenum Disulfide dry-film lubricant to further enhance smooth motion of the primer bar. The photo above shows the UniqueTek 550 Primer Track Bearing (left) compared to the original Dillon part (right). The UniqueTek 550 Primer Track Bearing is a drop-in replacement for the original Dillon Primer Track Bearing (part #14015) and takes just minutes to install. Features

|

||||||||||||||||

|

XL650 Live Primer Chute

The UniqueTek 650 Live Primer Chute eliminates the "ski jump" effect ... preventing primers from falling onto floor. It captures primers and holds them for reuse. The UniqueTek 650 Live Primer Chute is a "drop-in" replacement for the original Dillon Primer Chute (part #16210) and takes just minutes to install. NOTE: Will Not Work on Certain Older XL 650 Presses Features

The 650 Live Primer Chute will not work on certain older XL 650 presses. The Primer Chute on these older presses also serves as the mounting bracket for the Spent Primer Cup and looks like the one on the left in this photo. The UniqueTek 650 Live Primer Chute, does not have a place to mount the Spent Primer Cup.

|

||||||||||||||||

|

Spent Primer Chutes

No more spent primers bouncing out and onto the floor when you reload!Each Spent Primer Chute™ installs easily on your Dillon reloading press. Spent primers are routed through clear PVC tubing (included) into any convenient waste container. The Spent Primer Chute™ creates a fully enclosed pathway for spent primers ... so they simply can't bounce out!

|

Case-Related

|

Media Separator

|

A300060 |

Media Separator |

$60 |

The CED Media Separator is the ideal tool to quickly separate brass from media with a simple turn of a handle. Brass is caught in the separator while the media falls into the bottom of the separator kit. For the BEST results, fill lower container with water to separate Stainless Steel Media from the brass.

A103444 |

DAA Turbo Case-Feeder Plate |

$65 |

SPECIAL ORDER ITEM! May take 3-4 weeks to deliver

The DAA Turbo Case-Feeder Plate is a highly modified and evolved reloading accessory which will greatly increase the output speed of your current Dillon case feeder.

The plate is designed to handle all pistol calibers – from .380 to 0.45, so one plate can now handle all your pistol calibers!

** For the very long revolver cases (38SPL and 357) the plate must be elevated using a large washer (not included). Not recommended for use with .44MAG.

The DAA Turbo Case-Feeder Plate is built very differently from the original Dillon Plate. Our plate is much thicker, and incorporate deep feeding grooves into each of the 32 output pockets on the plate. These grooves greatly improve the efficiency of picking up brass as the plate rotates, ensuring that more of the pockets output a case, on each rotation. This increases the output speed by 30-80% compared to the original plate. (output speed gain varies per caliber. Highest gains are with 9mm, lowest with .45)

The thicker plate design also serves to offer better support to the cases as they drop out the exit hole, reducing the likelihood of them rotating on the way out and possible causing a hang-up in the output funnel.

The DAA Turbo Case-Feeder Plate includes an aluminum slip clutch assembly at its center, to insure the disc can slip and not stall the motor if a jam occurs. Our slip-clutch assembly includes a handy stainless steel D-ring which makes it much easier to grab hold of the plate from its center and lift it up off the motor shaft, and out the case feeder. (experienced reloaders will know that this can be difficult to do without such a feature, especially with a well-used, dirty plate/casefeeder)

The 292mm diameter of the DAA Turbo Case-Feeder Plate make it a drop-in fit for both the original AC Dillon case feeder, as well as the newer Variable Speed DC model. It will also fit and can be used in the Hornady case feeder as well.

A103442 |

DAA 550 Mini Case Feeder |

$210 |

SPECIAL ORDER ITEM! May take 3-4 weeks to deliver

The DAA 550 Mini Case Feeder will greatly improve the efficiency of your Dillon 550 reloading press! By automatically feeding the cases into the shell plate, this clever accessory allows you to keep your right hand on the handle as you operate the press, and eliminates the need to pick up and orientate each piece of brass manually and feed it into the shell plate. Your reloading will be faster, easier and more enjoyable!

Please be sure to watch the video tutorials on Setup and caliber conversion BEFORE attempting to use your 550 Mini Case Feeder!

Unlock the full potential of your Dillon 550 case feeder with this device, which ships complete and ready to use to load most pistol calibers, as well as .223 and .300BO.

You can switch calibers on the case feeder in under a minute, making this solution perfect for 550 reloaders who often reload many calibers.

Supported calibers include: .380ACP, 9mm, 9x21, 9x23, .38S, .40SW, .45ACP, .38SPL, .357MAG .223, .300BO*

* to use the case feeder with 300BO, you need to modify the Type A case slider adaptor, making it shorter by 1.5-2.0mm. You can do so using a file, Dremmel, or belt sander. After this modification the Type A spacer can still be used without issue for the .357, but it will no longer function with the 38SPL. If you require both 300BO and .38SPL calibers – contact us for a spare Type A spacer.

Your DAA 550 Mini Case Feeder includes the following parts:

Additional magazine tubes can be purchased separately, and we highly recommend the use of the optional Mini Case Feeder Bowl to greatly speed up the process of filling the tubes.

MINI CASE FEEDER NOTE: May not work with all Dillon Roller handles, as some seem to be more angled inwards towards the press.

A102385 |

9mm |

$80 |

A102386 |

.40 |

$80 |

The XL650 is a very popular press as it can add a bullet feeder to improve productivity. The Dillon case feeder is a great addition but at around $350, a bit of a hindrance at first purchase of all the other items needed to reload.

The Mini Case Feeder solves the problem allowing case feeder addition at a very reasonable price. Preload your case tubes with about 150 cases while watching TV, multitasking, and you are ready you are ready to go when you want to reload.

Note that you can use the 9/.38 kit for 38SPL or .357 however you will need to modify slightly the bottom of the adaptor - shorten the stem.

Bti116 |

Case prep centre expansion kit |

$50 |

Made of hardened high speed steel (HSS)

Large and small primer pocket uniformer/cleaner

Large and small primer pocket crimp remover

Standard 8-32 threads fits Case Trim & Prep Center’s auxiliary shafts

#C2100 |

TORNADO Tumbler Using Wet Media |

$480 |

SPECIAL ORDER ITEM! May take 3-4 weeks to deliver

The CED Brass Tornado, Pro Series Tumbler, is the Reloader’s dream machine! It is the most technologically advanced wet rotary tumbler ever! This new Pro Series rotary tumbler incorporates features and functions that have never been offered on tumblers before. Now it is possible to “fine-tune” the brass cleaning process, the time spent, and the results achieved.

The CED Brass Tornado incorporates so many features that others simply do not provide:

Included Key Features:

The CED Brass Tornado is the FIRST to feature variable speeds, variable forward / reverse direction options, On / Off / Start / Pause selection, up to a three-hour timer with alarm function, and memory. All in an advanced digital product designed by shooters for shooters! Featuring a high speed, powerful motor, a 3.5L tumbler drum capacity, which allows more than 450 -500 pistol or up to 300 rifle cartridges to be cleaned at a time. Capacity will vary depending on the caliber brass being cleaned.

More and more shooters are “wet-tumbling” their brass (in liquid) with reusable stainless steel polishing media, rather than using traditional dry media in a vibratory tumbler. The “wet-cleaning” method works best with a rotary tumbler fitted with a water-tight, horizontal drum to hold the brass, cleaning solution, and stainless, pin-type media. Through extensive testing, CED has developed an excellent cleaning combination of stainless steel media, water, Lemi Shine, and Lyman Turbo Sonic Cartridge Cleaner, which when combined results in glistening clean brass cartridges, inside and out, including the primer pockets. Our recommended combination, even seem to remove “water spots” and residue leaving shining, spotless brass that look like new!

The tumbler consists of a re-sealable watertight drum, a driving system base on which to place the drum, and a motor to rotate the drum at ideal speeds of 40-60 RPM. The speed is important - too fast and centrifugal force will cause the cases and media to cling to the sides of the drum with virtually no cleaning action whatsoever. Too slow, and the cleaning process is inefficient and extremely time consuming. This is one of the single failures of other rotary tumblers on the market today. They offer only a “fixed” speed. Unfortunately, depending on the weight of the contents being cleaned, the drum will spin at different speeds. The CED Brass Tornado solves this problem by offering variable speed selection from 5 RPM up to 100 RPM, allowing the user to select a faster speed for heavy loads or a slower speed for smaller load sessions. The CED Brass Tornado is designed with a hexagon shaped drum, which dramatically improves the cleaning process by creating more “tumbling” movement of the cases as they rub against each other and the steel media, which in turn removes all of the fouling and thoroughly polishes the cases inside and out, including the primer pockets when de-primed cases are in use.

The CED Brass Tornado a custom designed filtration cap that allows easy rinsing of the brass from the dirty water solution before separation and drying. Also included are 3.5 lbs. of stainless steel media, and a spare sealing O-ring. Also included are a sample of Lyman Turbo Sonic cleaner and Lemi Shine, an outstanding combination to produce “like new” results. The CED Brass Tornado comes with a complete two year warranty, and CED stocks a full line of replacement parts / accessories if ever needed. Net weight: 12 kgs. (26.4 lbs.) Dimensions: 27 W x 29 D x 32 H cm (10.75 W x 11.5 x 12.25” H)

Register your new CED Brass Tornado Tumbler at http://www.cedhk.com/tornado

Bti111 |

Stainless steel tumbling media 5lb |

$75 |

The Stainless Steel Media Pins are ideal for rotary tumbling brass. When combined with a liquid bath they deliver unmatched cleaning performance. Constructed of high quality 304 stainless steel, the media pins effectively penetrate inside of cases and into primer pockets.

- 304 Stainless Steel

- Ideal for Rotary Tumbling Magnetic for convenient handling Lifetime use

Bti113 |

Media Transfer Magnet |

$25 |

The Transfer Magnet is ideal for handling stainless media pins. It effectively gathers and then releases pins with a pull of the handle. Makes separating pins from brass fast and convenient.

- Easily handle and transfer 304 stainless media pins

- Gathers then releases when handle is pulled

- Ideal accessory for rotary tumbling

Bullet-Related

|

Mr. BulletFeeder

|

Mr. Bulletfeeder pistol cartridge |

$755 |

|

calibre conversion when you change cartridges |

$245 |

|

Mr. Bulletfeeder .223 Rem |

$775 |

|

.223 Rem conversion |

$280 |

|

Mr. Bulletfeeder .308 Win |

$815 |

|

.308 Win. conversion |

$295 |

You will wonder how you ever reloaded without one...

If you reload a lot, you quickly appreciate the efficiency and reliability of this ingenious patented system.

Please note: All pistol calibers use the same output tube, lead spring and spring adaptor cap. So this assembly is not included in the conversion kit –as you will not need a second one when changing pistol calibers.

The rifle calibers too share the same output assembly, and so when converting from 223 to 308, the same output assembly is used.

However – if you intend to buy a conversion kit to convert a rifle unit to a pistol caliber, you must purchase the output assembly required, in addition to the conversion kit.

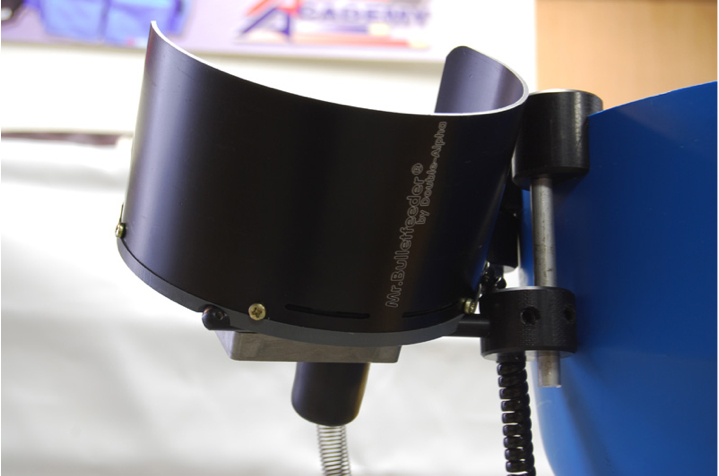

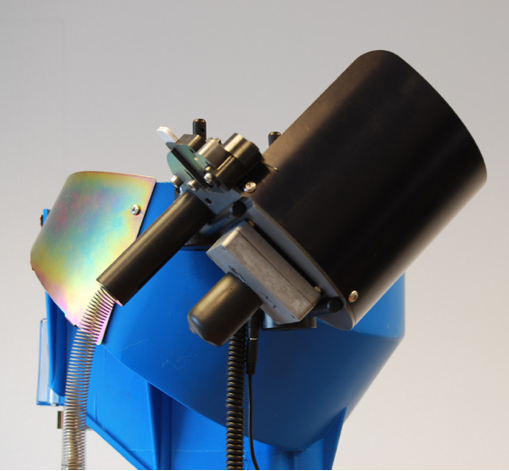

We are proud to introduce the new Mr. Bulletfeeder® by DAA. DAA and RAK Systems have teamed up and have retooled and redesigned the Mr. Bulletfeeder®, which is now manufactured by Double-Alpha Academy. The new system, manufactured under license by RAK Systems, is lighter in weight and more compact than the previous models. It is easier to install and set up, and has a more professional “production” look and feel.

An entirely new US Patent Pending dropper system allows the new model to function better and longer than before. The new dropper design eliminates the need for any spring or small plastic parts in the dropper head, and works entirely powered by gravity and an ingenious geometric design.

If you have never tried a bullet feeder on your progressive reloader - what are you waiting for?! It cuts the time and effort involved in reloading practically in half! A must-have item for any serious shooter.

Mr. BulletFeeder Mounting Platform |

$50 |

A102554 |

Now standard on all Mr. BF but makes a nice upgrade that is simple to install, move, etc. It now makes tilting faster and easier to do if needed. Just clamps on to the side of the case feeder.

Mr. BulletFeeder Dropper Assembly |

$140 |

A101316 |

9mm |

The Dropper Assembly is needed for shooters who wish to set up a second tool-head in the same caliber, and wish to quickly transition from, say, 9mm to .38 Super. Or from one 9mm bullet to another. A change is needed to the collator parts, and if a 2nd tool-head is to be used on the progressive reloader, it is quicker and easier to leave an adjusted Mr.Bulletfeeder dropper on each tool-head. This allows for quick swapovers, without the need to calibrate or adjust the dropper.

Note that in most cases you will need to purchase an additional Powder Funnel for your second tool-head’s powder measure, as our expanding powder funnel is required for troublefree reloading.

Mr. BulletFeeder PRO Dropper Assembly |

$250 |

A102549 |

9mm |

The Dropper Assembly is a critical component of the bullet feeder, and in the PRO model it has been further evolved and improved. Also works with the original Mr. Bullet Feeder as an upgrade.

The Dropper Assembly is a critical component of the bullet feeder, and in the PRO model it has been further evolved and improved. Also works with the original Mr. Bullet Feeder as an upgrade.

Since the dropper is gravity powered, by increasing the weight of the assembly we are able to get a more reliable and more consistent performance. In the case of the PRO dropper, the brass section is twice as long and so twice as heavy as the original Mr.Bulletfeeder, preventing hang-up which could happen due to excessive feed-spring sideways tension or friction to the dropper.

The Mr. Bulletfeeder PRO dropper uses all-steel parts for the die section to further add weight and durability for the large volume reloaders.

Note that in most cases you will need to purchase an additional Powder Funnel for your second tool-head’s powder measure, as our expanding powder funnel is required for troublefree reloading.

A103337 |

Dropper-Tensioning Spring Assembly |

$30 |

The Mr. Bulletfeeder dropper is gravity powered. When the case retracts, the inner dropper tube retracts with it, and the steel balls in the die move into place and close under the next bullet, ensuring only one bullet is released.

That is how it is designed to function, and how it does normally function – provided the dropper is free and clear and able to drop quickly, as designed, with the retracting case.

However, in some cases, the feeding tube spring adds side tension onto the dropper head (an issue more common on those machines where the toolhead moves up and down), or the dropper body may make contact with a close by die, creating friction that does not allow the dropper to move smoothly and quickly enough. Resulting in an occasional 2nd bullet falling out the dropper onto the shell plate.

The Mr.BF Dropper-Tensioning Spring Assembly is now available to resolve this problem for those experiencing it. This solution includes two carefully selected tension springs and two printed parts designed to fit onto your Dropper. The lower nut can be adjusted higher or lower on the die section to control how much extra downward force you are adding. It is recommended to add as little as possible additional tension, as too much force will increase wear by the case mouth on the dropper funnel below.

The upper collar assembles around the brass weight section, and rests atop the set screw, which you may need to back out a little to allow the support required. Multiple positioning tabs allow you to find the right angle for positioning the springs, without interfering with nearby dies or powder dropper.

The lower collar screws onto your die section, above the lock nut, and allows you to adjust its height to control the added downward force.

The double spring system creates a balanced and symmetrical downward force, that allows for smooth function of the die. The extra downward pressure will ensure that the dropper follows the extracting case, overcoming any friction and preventing those occasional annoying extra bullets from falling.

Mr. BulletFeeder Die Assembly only |

$90 |

A101431 |

The Mr. BulletFeeder Die Assembly only is available for 9mm/.38Super, .40SW, .45ACP, .223 Rem & .308 Win, please specify.

Mr. BulletFeeder Powder Funnel |

$65 |

A101289 |

The Mr. BulletFeeder powder funnel is available for 9mm/.38Super, .40SW, and .45ACP, please specify.

Mr. BulletFeeder Output Assembly |

$45 |

A101349 (Small, rifle) |

2-in-1 Seating Crimping Die |

101922 9/.38

|

$40 |

I sell quite a few Mr. Bullet Feeders and a common question is will they fit a 550 or can they fit with the Dillon powder check system, 21044, on my 650. Now they can by using this die to combine bullet seating and crimping in one station which frees up a station the Mr. BF needs.

These dies are made by Lee Precision to DAA standards. These quality stainless steel dies produce quality ammunition. It will take a bit of monkey futzing around to get the adjustment correct but once calibrated correctly will produce consistent and precise quality ammunition.

These dies include an O-ring lock machined into the nut which allows you to hand tighten only - and the die stays put! The die includes a finger adjustable floating bullet seater and are heat treated to ideal hardness then polished to a smooth finish.

Ammo Gauges

|

Shockbottle 100 Round Ammo Gauge

|

SB107 |

9mm Luger, silver |

$165 |

Note that only silver is available at this time.

These chamber gauges are ideal for reloading and shooters who want to ensure better reliability of their ammo in chambering and extracting. They are machined from aircraft grade aluminum and hard anodized using S.A.M.M.I. spec's(May reject lead, moly, and long 40 loads). This chamber gauge is specifically designed to utilize a 100 round ammunition box as a "flip-tray", then can be flipped into an ammo box bullet down and ready for the range.

Reliability starts with good ammo, and everyone who reloads understands what a fat case does to your time when it gets stuck in a barrel. Once you have had an ammo related jam, you will realize the time to gauge your ammo is worth any price. Now thanks to Shockbottle case gauges, there is no reason not to. It is fastest way to make sure your ammo won't cost you a match. It checks 100 rounds at a time, the fat ones stand out like a sore thumb and also lets you see those high primers and easily mark your brass.. CNC machined and finish-reamed to minimum chamber dimensions means, if it goes in the Shockbottle case gauge it will go in the chamber of your barrel. Made from aircraft aluminum to last.

Load the gauge up with ammo, place an ammo box over the Shockbottle case gauge and flip. Put another box over and flip again if you want bullets-down. I tried this and it works GREAT!

7-Hole Handgun |

E70140 |

.45 ACP |

$38 |

7-Hole Rifle |

E70150 |

.223 Rem |

$55 |

Anyone who reloads knows that practice ammo doesn't get the same TLC that match ammo does. I ALWAYS gauge my match ammo. At matches I see too many who don't and they have malfunctions that are not gun related but ammo related.

Chamber checkers have been around a long time as has EGW. I first met them at US Nationals back in the late 1980's which tells you they must have good product to survive this long. I first started using the multi chamber checker for .40SW and have moved to 9mm Luger for my Open gun. These little beauties save time in the last process before boxing and labelling your match ammo. The price difference is little to a single gauge.

EGW’s Chamber Checkers are machined from solid 6061 T6 aircraft grade aluminum.

While some companies use boring bars to make chamber checkers, EGW uses the actual Clymer reamers that are used to chamber barrels.

Anodized matte black for durability.

Oops! Pullers & Squib Rods

|

Squib Rod ("Stupid Stick")

For those RARE instances when your “friend” forgot to put powder in the case and the bullet is lodged in the barrel. I designed this rod in brass to save the barrel but with a steel cap so you can hammer on it and not peen the end over as you would with brass. The other end is dimpled to take the nose of the bullet... or to avoid whacking the primer! They are designed to fit 9mm, or .343”, with an 8” effective length. |

Got my Dillon Square Deal parts yesterday at no charge and without any hassle, don't think I would buy any other reloading equipment unless its a Dillon. Thanks!

Murray, thanks again for solving my Dillon parts problem. Your innovative approach and customer service first attitude in accommodating my request is a model for others to follow.

Well, I have to say thanks for setting me up with that 550 press. WOW, what a difference! Not a single malfunction, every round cycled the gun flawlessly. I didn't think re-loading would make that much difference, but it does. This now changes my whole outlook on shooting!

Thank you very much for ordering the primer feeder for me, and your valuable time arranging the delivery. The primer feeder is so efficient that reloading is no longer a boring job now.

|

||||||

Welcome to mdgardner.com! |

(C) Murray Gardner 2002-2024. All rights reserved.

|

|||||